-

АлександрДостоверные поставщики

АлександрДостоверные поставщики -

ЛуисБыло приятно работать с вами.

ЛуисБыло приятно работать с вами.

Энергосберегающий экономизатор котла с производительностью пара до 20 т/ч и 5-летней гарантией на основные компоненты

Свяжитесь со мной для бесплатных образцов и купонов.

Ватсап:0086 18588475571

Вичат: 0086 18588475571

Скайп: sales10@aixton.com

Если у вас есть какие-либо проблемы, мы предоставляем круглосуточную онлайн-помощь.

x| Тип | Естественная циркуляция | Структура | Огневая труба и водяная труба |

|---|---|---|---|

| Давление | Низкое/высокое давление | Производство пара | Максимум 20 т/ч |

| Стиль | Вертикальный | Топливо | Уголь / Газ / Угольное топливо / Водяное тепло |

| Выход | Горячая вода/пар | Обработка поверхности | Окрашен |

| Материал | Сплавная сталь, углеродистая сталь, SA210C, SA213T22 | Материальный стандарт | Astm, en или iso |

| Веса диапазон | Мин: 10 тонн, макс: 1000 тонн | Процесс плавки | EF+LF+VD |

| Процесс | Материал-> Стог-> Горячий/холодный ролнг-> ТЕПЛОЧНА | Стандарт UT | ASTM A388 или EN10228 |

| Термическая обработка | Нормализация+ отпуск | ||

| Выделить | Экономайзер для паровых котлов мощностью 20 т/ч,Гарантия 1 год Экономизатор отработавших газов,5 лет Гарантия на основные компоненты теплообменник |

||

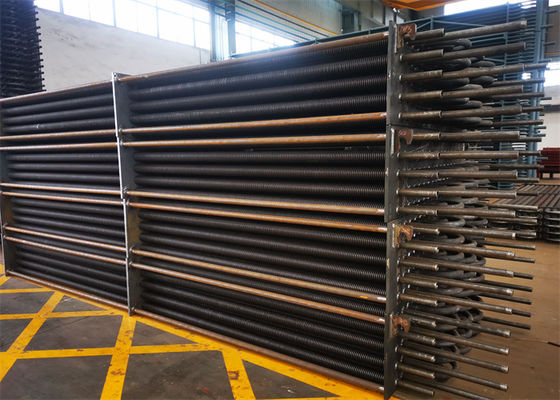

Экономизаторы котлов - это высокоэффективные теплообменные устройства с оперенными трубками, предназначенные для нагрева жидкостей (обычно воды) без превышения температуры кипения жидкости.Мы производим три типа экономизаторов котлов.:

- Экономизаторы для голых труб

- Экономизаторы труб с H-пеленой

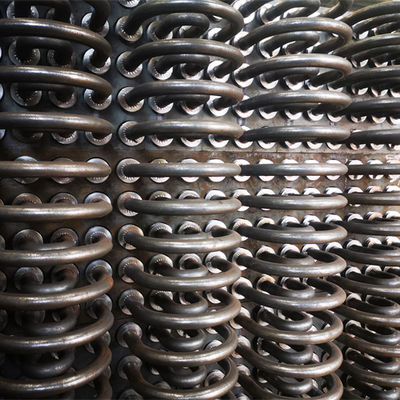

- Экономизаторы для труб с спиральными плавниками

Экономизатор трубки с H-плюсками - это особенно эффективный теплообменник, состоящий из H-плюсков.

- Расширенная область теплообмена

- Уменьшенное количество необходимых труб

- Увеличенная площадь потока дымовых газов

- Сниженная скорость потока дымовых газов и абразия

Наш экономизатор с спиральными плавниками имеет инновационный дизайн с спиральными трубками, которые преодолевают распространенные проблемы с износом и коротким сроком службы.

Как следует из названия, основная функция экономайзера заключается в том, чтобы "экономить" - значительно снизить затраты на охлаждение, позволяя отключить компрессор при сохранении достаточной охлаждающей мощности,что приводит к значительной экономии энергии.

| Описание | Экономизатор котла |

|---|---|

| Материал | Сплавная сталь, углеродистая сталь, SA210C, SA213T22, и т.д. |

| Стандарт материалов | ASTM, EN или ISO и т.д. |

| Размер | Конфигурация |

| Вес | Минус: 10 тонн Максимум:1000 тонн |

| Процесс плавки | EF+LF + VD |

| Процесс | Материал→Инготация→Горячее/холодное прокатение→Теплообработка (нормализация + закаливание)→Инспекция→грубая обработка→УТ→Вторая теплообработка→окончательная обработка→Инспекция |

| Стандарт UT | ASTM A388 или EN10228, и т.д. |

- Отчет об испытаниях на удар и расчете прочности с информацией о применяемых материалах

- Отчет о 100% НДТ (неразрушающей проверки) стальной пластины, трубки и электрода

- Отчет об осмотре рентгеновского, γ-лучевого и жидкостного проникающих материалов (сварный швов) для обеспечения полного качества котла

- Отчет о гидравлическом испытании для проверки стандартного рабочего давления и безопасности